PressCamp '16: Koroyd

Whilst looking through the list of exhibiting brands in preparation for PressCamp 2016, I came across a name I had a vague recollection of; Koroyd.

Whilst looking through the list of exhibiting brands in preparation for PressCamp 2016, I came across a name I had a vague recollection of; Koroyd. I couldn’t quite recall what products came under this name, and whether it was an apparel or some kind of accessory brand. Turns out where I’ve heard the name before is actually from another brand; Smith Optics. While Smith are the maker of the brilliant Overtake and Forefront helmets, Koroyd is the manufacturer of those fluoro-green panels used inside the helmets.

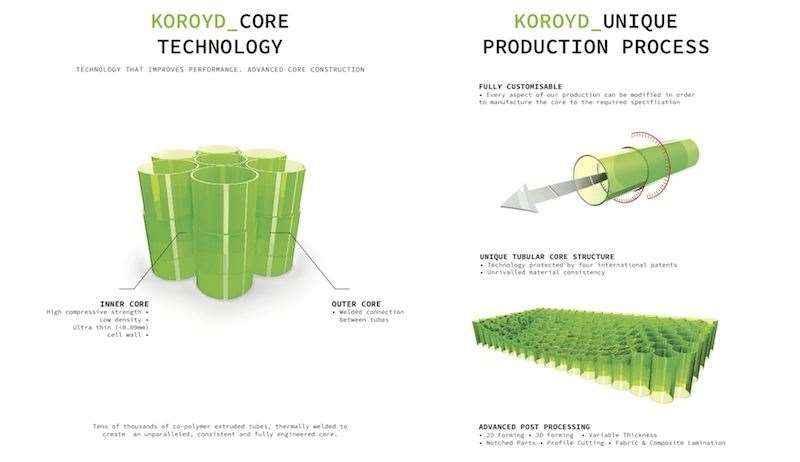

Those fluoro-green panels are made up of hundreds of small plastic tubes that are fused together with heat, and they’re designed to crush under impact to help absorb and reduce that impact energy from making its way to the riders skull. Compared to EPS foam, they can take a harder hit, and they can absorb it in a much more linear fashion too. Because of their hollow construction, the tubes also aid with breathability, which makes it an ideal application for bicycle helmets.

As it currently stands, Smith Optics is the only helmet manufacturer utilising Koroyd technology in cycling lids. Koroyd is also used in other applications too, such as in snowboards and skis, bulletproof vests, and back protectors. However, just like MIPS, Koroyd is a technology that will eventually be licensed to other manufacturers, so those who see the benefits of the design will be able to use it in their helmets too. So exactly what advantages does Koroyd offer to cycling helmets?

During the development of Koroyd for helmet applications, the company invested a huge amount of research and development to identify what current helmet safety standards are in place around the world, and what those standards actually mean. Most helmet standards are based around an anvil strike test in order to determine the maximum acceleration of the helmet when it hits the ground or an obstacle. As long as the helmet doesn’t exceed a certain amount of acceleration, then it will pass. What the tests don’t take into account however, is the duration of that impact (how long that force is being applied for). According to Koroyd, this is a problem, because the longer that force is being pushed onto your head, the more damage will occur. Looking for guidance, Koroyd then went to the automotive industry to see what research had been carried out there for passenger safety, and the risks involved with sustained impact damage to the head. As it turns out, the standards used by the automotive industry require a much lower risk level than what a cycling brand must adhere to…

“While the automotive industry has advanced the safety of cars continuously for decades, international bicycle, motorcycle and snow helmet safety standards have hardly changed in the past twenty years. At the same time, the correlated risk of suffering a skull fracture or a fatal traumatic brain injury at the accepted limits in these safety standards is still very high. Koroyd, specialist in energy absorption materials, has launched the Helmet Safety Initiative, an initiative to educate riders on the risks of suffering severe head injuries and a call to manufacturers to build the next generation helmets, with significantly improved energy absorption capabilities. Helmet safety standards govern the maximum allowed deceleration of the head when it impacts onto a surface.” – Koroyd

“Many of the international standards allow a maximum deceleration at the reference impact velocity between 250 and 300 g, which is associated with risks between 40 and 79% of suffering a skull fracture, based on Prasad/Mertz head injury risk curves used in the automotive industry. The European motorcycle helmet safety standard uses a more advanced metric called the Head Injury Criterion (HIC), that not only considers the maximum deceleration, but also the time duration of the impact. While the accepted value within the automotive industry ranges from HIC 700 to HIC 1000, a motorcyclist is allowed to be exposed to HIC values up to 2400, correlating with a 97% risk of suffering a severe traumatic brain injury and a 77% risk that the impact is fatal, according to the risk curves.” – Koroyd.

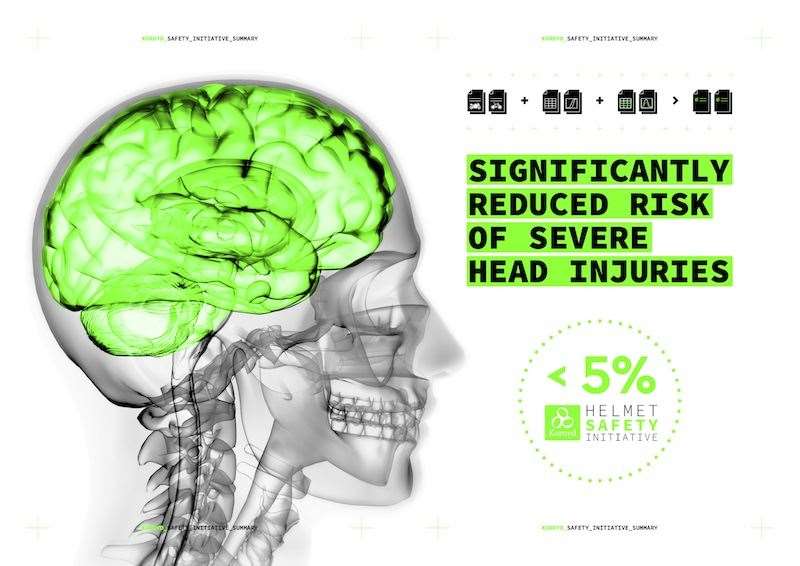

The aspect that I found interesting as part of Koroyd’s research, was that all of the current bicycle helmet safety standards in use around the world are at least 20-years old. As most people would already understand, the cycling industry has progressed tremendously in the past two years, let alone the past two decades. The frustrating aspect for those interested in helmet safety such as Koroyd, is that these standards move very slowly, and so change is unlikely to happen anytime in the near future. Having recognised just how lacking these current standards are in addressing the affect of impact forces being applied to a riders helmet over a longer period of time, Koroyd have decided to launch the <5% Helmet Safety Initiative. This initiative is an ambitious campaign to raise awareness on helmet safety, and to educate mountain bikers and road riders on what the current safety standards mean, and what they don’t take into account.

“We believe the industry needs to challenge itself to finally outperform these outdated safety standards. Significantly less deceleration and less energy transferred to the skull and brain can reduce the severity of many future head injuries and save many lives. Using the knowledge on head injury tolerance from the automotive industry will allow manufacturers to confidently build helmets which offer more protection and communicate this to consumers, allowing them to make a more informed purchasing decision.” -John Lloyd, Managing Director at Koroyd.

Of course for Koroyd, they have a vested interest in this safety campaign. They license and sell their technology to helmet manufacturers, and one of the purposes of the safety campaign is of course to raise awareness of their own product within the market. And they’ll be able to do that easily because their product works. In testing, Koroyd have found that applying their technology to a bicycle helmet can drasticallyreduce the correlated risk to the rider of experiencing a skull fracture or a severe traumatic brain injury. Ultimately though, Koroyd just want riders to use safer helmets. They know that other helmet manufacturers will have different technologies and means for reducing risk for their riders, and as far as they’re concerned, the competition between brands can only mean good things for riders.

Will the safety initiative take off? We shall just have to wait and see, but at the very least, Koroyd must be commended for their enthusiasm and willingness to challenge the status quo.