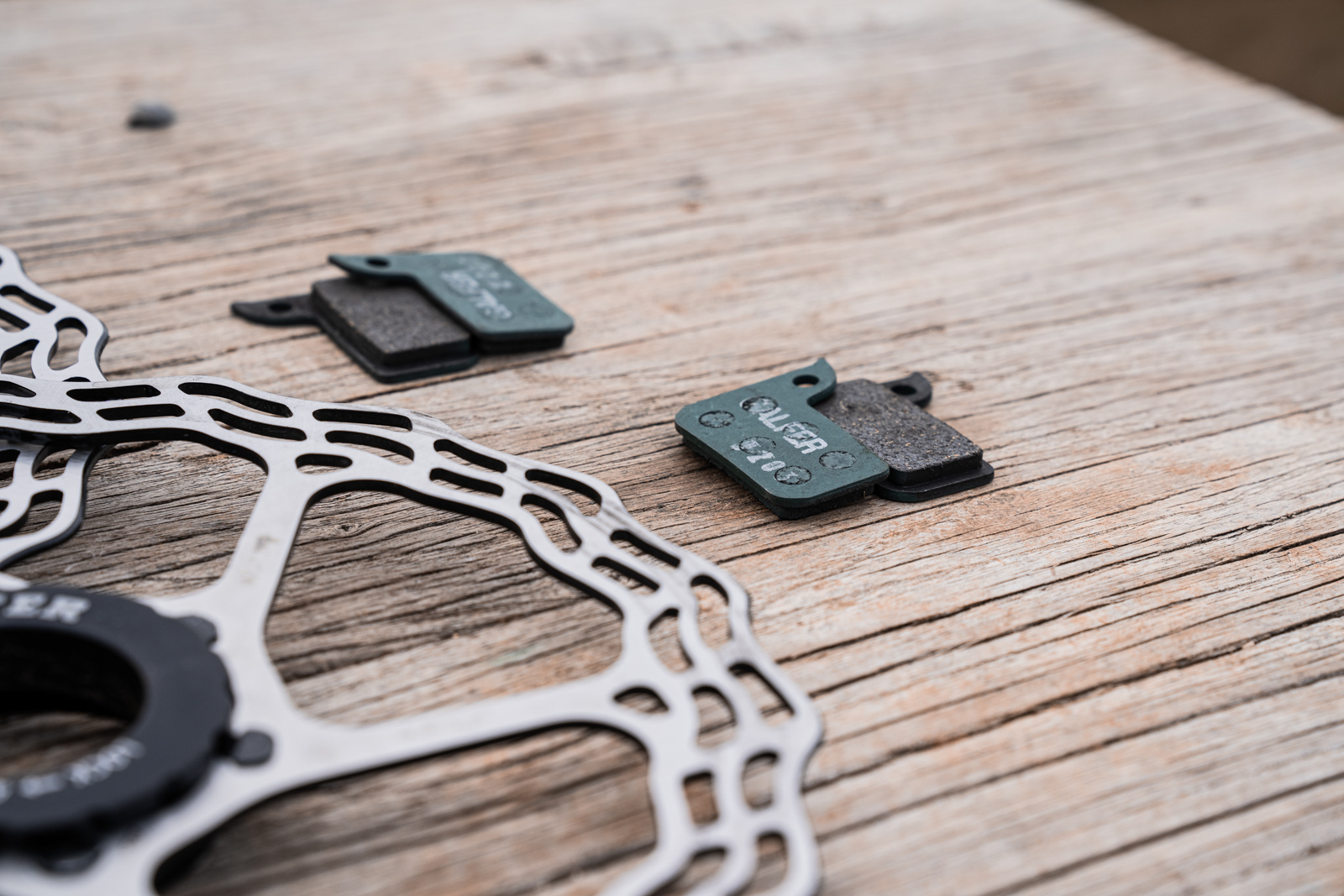

TESTED: Galfer Pads and Rotors

Ben Morrison puts Galfer's brake products to the test.

Words: Ben Morrison

Photos: Georgina Von Marburg

Galfer is one of the world’s leading manufacturer of friction materials (pads and rotors) for the motorcycle word. Founded in 1952 and with innovation as its driving force for more than 60 years Galfer has reached the top of its game in motorsport.

All Galfer products are manufactured in their 6000 square meter factory located in Granollers, Barcelona – Spain. This is also home to their own team of engineers and testing facilities where the strictest guidelines are followed in the development of all new Galfer products for both powersports and cycling. The experience Galfer has in the high-powered and high-risk world of Moto GP tends to lean into their high quality of product. Their team in the R&D department combines passion and enthusiasm with the latest technology to offer the highest quality final product, that Galfer say will offer improved brake power, reduced wear, and less noise.

But what about brakes on mountain bikes?

Something to think about when looking at replacing both your pads and rotor is were you happy with their performance? Like tyres, better performance from brake pads often means a shorter life span and just like tyres brake pads and rotors (rotors do wear down especially on an eMTB) are a consumable item.

Lots of brands, including the people who made the brakes that came on your bike, make brake pads for different applications. These could be designed for wet conditions, more power and even ones designed to simply last longer.

Picking what’s right for you can be very easy. If you were happy with how your brakes work then replace the pads with the same ones that were on there.

Something to note is that most bikes tend to come with the longer lasting pads in them from new. These won’t offer as much power and for some brands make less noise. The downside to this, because of the way disc brakes work most of the brake manufacturers do not recommend using different types of brake pads on the same rotor as they may not work as intended. So, if you are chasing a different type of pad its best to change rotors too.

How disc brakes work 101:

When new a disc rotor will work with any pad compound unless it’s made of Carbon Fiber. What happens during the run in process (when your brakes do not work and slowly improve over a ride) is the brake pad transfers the material they are made from to the rotor. It is this transfer of material that creates friction and your stopping power. This is why if you replace your old pads with the same type, they work right away and if you don’t they kind of well… don’t.

With the large range in rotor sizes along with increasing compatibility of frames and forks with large rotors you can often get a little compromise going. If you’re happy with the power you had but want a little extra life from your pads, try going up a rotor size. The larger rotor will offer some more power and better heat dissipation mixed with the longer lasting pad things should all come out in the wash giving you the power you had before with a little more life in the pad.

Galfer’s range of brake pads and rotors:

Galfer offer an excellent range of pads and it really shows their racing pedigree when you have options like, Wet/Muddy, Competition, Trials, Universal as well as Ebike!

I tried 3 types of pad and had a think about the bikes and riding we were doing before ordering them from FE Sports. I chose Black (Universal) on my gravel bike as it would see the biggest range of conditions but also require the least amount of raw power due to the lower speeds. Next up it was the Green (Competition) pad that was to go on my short travel trail bike. Finally for my eMTB I went the purple (Ebike) pads. In the interest of creating a baseline of sorts I used the same model wave rotor, just changing the mounting style and the rotor size specific to each bike, being 6 bolt or centre lock.

The rotors boast an anti-corrosion finish and heat treatment for more consistent braking, along with temperature management and dissipation to prevent warping and come in 6 bolt, centre lock (including lock ring!!!) and every size you can think of. Their prices run from $59.95-$94.95 depending on size and fitment.

Galfer Ebike brake pads:

It’s great to see more eMTB specific products coming out, as brake performance can often be overlooked on eMTB. Some brands like Trek spec 200mm rotors front and rear on a medium sized Rail eMTB. This is great and a step in the right direction that some brands do not do in order to save weight on the 20+kg eMTB – I’m not sure I follow the logic!

If a rider is say 80kg and once they have all their gear on they are now 85kg, then they jump on a 22kg bike. Those brakes are suddenly having to pull up over 100kg and often more, over and over again. It’s a big job.

This is where Galfer have done a standout job and by all accounts have not produced a product that is more expensive than a standard product. I fitted the largest rotor Galfer make being 223mm on the front and stuck with a 200mm rotor on the rear due to clearance – always check what’s possible on your own fork and frame before ordering. The larger rotor and the eMTB pads were a noticeable improvement on the stock setup. The confidence descending and increased modulation really helps getting the heavier bike around steep and tight trails and even let me to pull off some car park stunts with rather long nose wheelies. These kinds of upgrades don’t have to be done right away, but should be considered when it comes time to replace items, even for lighter riders as more modulation means less effort not just more power.

Galfer Universal Pads:

You might think putting a gravel bike in the mix is a little odd, but they are proving to be more and more popular as a second bike for lots of people that do not want to do the dance with cars and still want that dirt fix. Think of it as a gateway bike for roadies to get into mountain bikes – or vice versa.

My gravel bike is fitted with 160mm rotors all round and they use the centrelock fitment. Galfer must be applauded here by suppling lock rings with their rotors, not everyone does this. Using the Black (Universal) pad there was no ground-breaking changes to the SRAM Force AXS brakes over the stock brake pads, but I did note that after around 1500km that the pads do look very much new, and this includes riding in some rather wet conditions. When you think about it the pads have done exactly what they have been designed to do which is offer durability though several conditions. Universal pads will therefore be a very popular model for the majority of riders.

Galfer Competition Pads:

Competition or race is often used to describe a product that is best of the best and going to give you ultimate performance over a standard product. This is what Galfer set out to do with their Green (Competition) pads. What is interesting about these Green pads is Galfer call them “For Competition, no need running in”. This is a rather odd claim! Based on how we know disc brake pads and rotors work to create friction and stopping power it would seem like perhaps this is a bad translation to English?

I installed the Competition pads and ripped off to the trails without the standard running in protocol to see how things went. Truth be told before reaching the trail head it was apparent that running in was going to be required or some seriously more than normal gas to flat action was going to be had on a certain trail at Stromlo Forest Park.

After more in-depth testing? Check out some more comparative articles here.

25mm vs 30mm rims for mountain biking

TESTED: Pirelli Scorpion Trail and Enduro Tyres

With the running in process well and truly behind me and with several rides under my belt I thought it prudent to switch back to the pre-Galfer pad and rotor setup in order to really get a feel for the difference in claimed power that these green pads provide.

To do this I rode the same trail 3 times in a row with the only down time between runs being the time to change pads and rotors (yes, I drove up to reduce the time between runs). The first run was with the Galfer setup I had been using, then switched back to the stock setup and finally finishing back on the Galfer setup.

It was not until the 3rd run switching back to the Galfer setup where I really noticed the difference. The power and modulation offered by the Galfer setup was notably better than the stock setup under hard on-off braking.

It’s not all roses though as there was some noise as you ever so lightly drag the brakes (this could have been a dag or bur on the pad). I still got the Magpie warble some metal pads are known for so no real changes there – this isn’t a miracle cure for that.

Final thoughts:

Brake pads have been designed to enhance your ride whether it be on the road, trail or gravel delivering long-lasting predictability throughout the life span of the brake pads, improving bicycle control, increasing rider confidence, and delivering a sense of security to the rider.

I liked the Galfer range given they have options with organic and semi-metal compounds – and they all ran very quietly. I did find there was an increase in positive lever feel, with more progressive braking and better braking power, especially with the Competition pads.

Galfer pads are available in 6 different pad types to suit rider needs, ranging in price from $24.95- $44.95 depending on your brake model and brand. But whether you’re looking at what Galfer offer or another brand, take a closer look at the range on offer and rotor sizes so you can find the perfect match for your braking needs.

After more component tests? Click here.