WORKSHOP: 9 Tubeless Tips for Success

Here's a few tips to get right to make sure you swear by, and don't swear at, your tubeless system.

Words: Mike Blewitt

Photos: Mike Blewitt, Nick Waygood

Tubeless systems are only as good as how you set them up and maintain them. If you've been having issues with your tubeless setup, go over the below to make sure you're following best practice.

1. Use the right valve

Most valves now have a conical end which is quite universal, but older rims often needed specific valves. Make sure you use a valve with a replaceable valve core, and aim to keep a few in your tool box. The valve core will clog over time, so being able to replace it is useful. Some valves have a wider bore (up to 3mm) that allows better airflow.

2. Tape is everything

Your tubeless tape creates the airtight seal on your rim. Don't neglect poor tape or poor taping, it might be what's letting you down. Match the tape to your rim width, and use a tape with some elasticity, then wrap it tight! Start before the valve hole and extend beyond it. Smooth it all down to remove creases. Take care when adding the valve hole.

Factory wheels should come with very neat tape. If not, or if your tape is creased or cracking – replace it before trying to get the tyre to seal.

3. Try a sealant syringe

Effetto Mariposa and Ride Mechanic both have sealant syringes, although the latter is predominantly designed to remove old sealant without breaking the bead. These tools let you set the bead and check your system dry, and then you can add the sealant through the valve stem afterwards.

This way you can check for tiny leaks using a tub of water, or a soapy water spray, before committing to adding sealant. It can end up far less likely to leave a mess.

TESTED: Ride Mechanic Sealant Exchange Kit

4. Nothing lasts forever

Have you found you've got a flat, and the sealant does nothing? Well, sealant doesn't last forever. It can dry out or separate, and lose it's effectiveness. Some of the most effective sealants dry out faster. A few brands make stickers so you can put a note on the rim – but white electrical tape and a permanent marker means you can do this yourself just as easily.

READ: The Great AMB Tubeless Sealant Test

5. Does your casing want to seal?

Almost all tyre brands will have a TR (tubeless ready) casing and bead, but there are still tyres out there that may be too thin. You should also check that your tyre casing is up to the riding you're putting it through. If you're always cutting tyres, or rolling them on the rim – it might be time to move up a casing level.

6. Are you using the best sealant for you?

Some sealants are race specific, and plug a hole in no time. But because they react so quickly with air, you will also find they dry out in a matter of days! Read the description of the sealant, and you'll find out more about how much you need to use for your tyre size, how long it should last, what temperatures it works in, and what size hole you can expect it to fit. Most brands have more than one sealant, so do your homework.

7. Don't top up!

If you want high quality sealant that works – why would you top up your old, crappy sealant with new sealant? The result is a mix of old and new. Start fresh each time, to make sure you have the best tubeless sealant quality. You can use the Ride Mechanic Tubeless Exchange Kit to syringe the old stuff out and fill up with fresh sealant – all without breaking the bead on your tyre. If you've got a date on your rim for when you put the sealant in, this is easy to plan around.

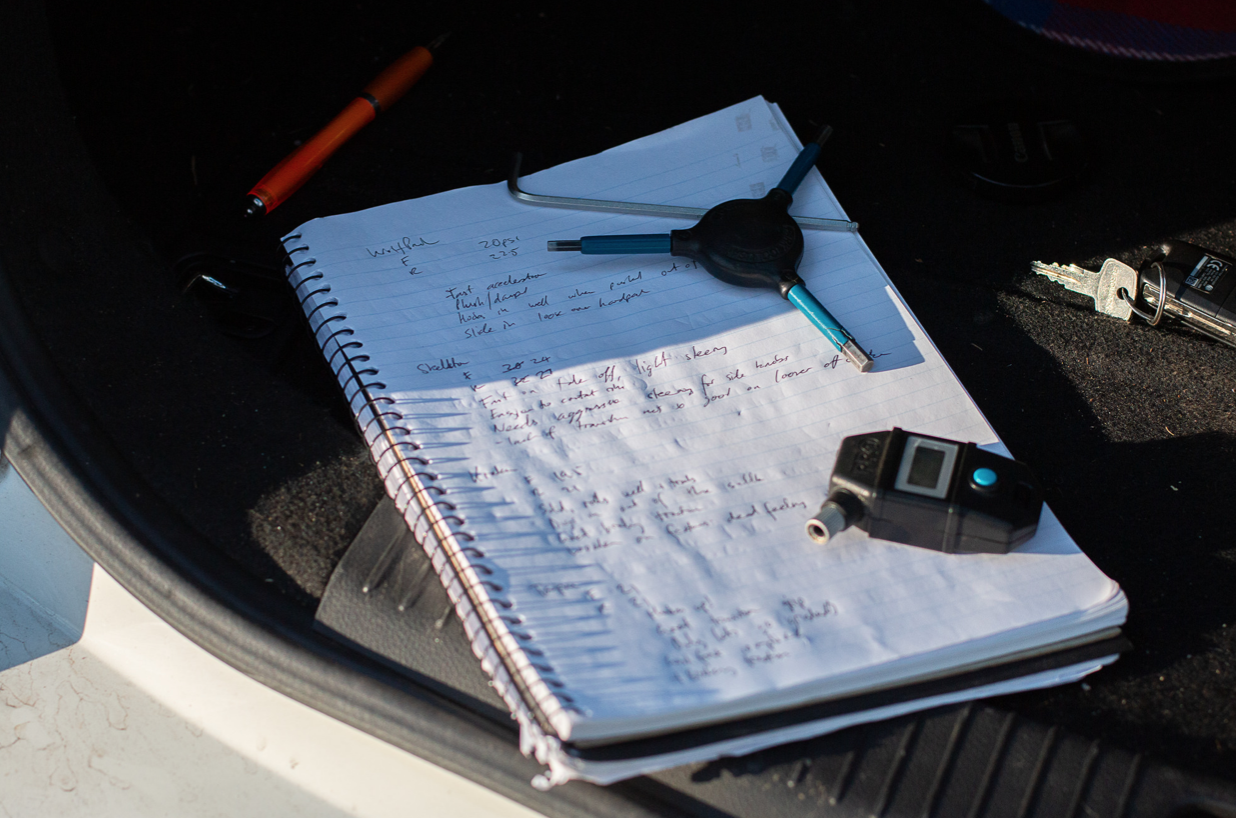

8. Understand your tyre pressures

With higher volume tyres and wider rims, our operating pressures can edge lower. So it pays to be precise. If you're getting flats, it may be more about a user error than a system error. While paying attention to your sealant type, sealant age and tyre casing is important – tyre pressure is key! Do your own testing to find out what works on a known trail, and use a digital pressure gauge so you can have your bike dialled before you go for a shred. You'd be amazed at the difference even 0.5psi can make.

9. Carry repair options

A flat tyre that sealant won't fix doesn't mean a tube has to go in right away. Plug kits like DynaPlug and the Stan's DART allow you to plug a hole in the tread, to reduce the size of the hole the sealant needs to seal.

READ: How to use Stan's DART

It all relies on air pressure, so the key is being quick. Don'y bury your plug kit deep in a pack, keep it handy and know how to use it, so you can save your ride – or someone elses.

READ: How to use a DynaPlug