Norco Optic C3 custom build

We custom built our Norco Optic C3 long term test bike with 2021 Fox 34s and Deore 12 speed.

In March I took delivery of an all-new long term test bike. In the same vein as the Transition Smuggler Carbon long term test bike I played with in 2019, the Norco Optic C3 was chosen for the versatility it offers in a trail bike sense. With 140mm of fork travel and 125mm rear, it would be easy to gloss over a bike like the Optic if you had a preset idea of the amount of travel you were after.

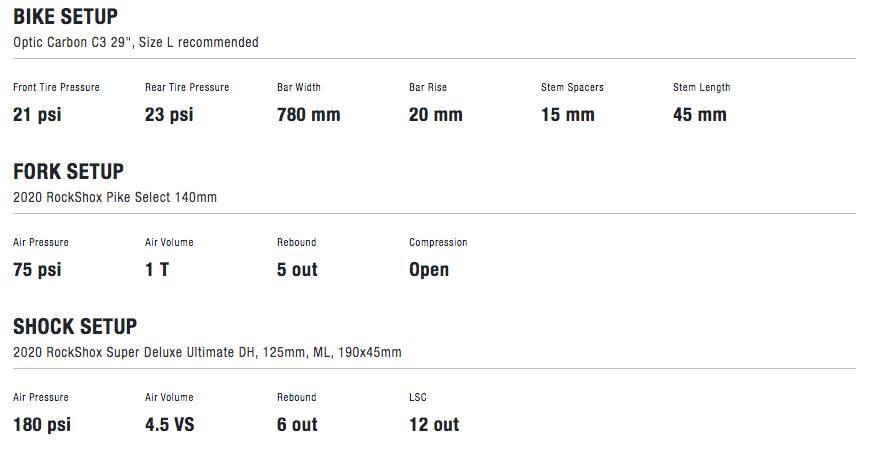

The 2020 Norco Optic has very aggressive geometry, something echoed in Norco's updated range from the Revolver XC bike all the way through to the Sight, and the Sight VLT as well. Modern Norco bikes have a very long reach, slack head angle and steep seat tube, with chain stay (rear centre) lengths that vary with the size that you're on. The real magic comes from the Ride Aligned system. More than just some triangles thrown together by a designer, Ride Aligned is software that has data on most of Norco's trail bikes, then size data from you and setting options from the components to create a setup guide for your riding style and ability.

It's that last bit that makes the real difference. While we might all have the thought that we are expert riders, you really need to put yourself in the bike designer's shoes. Norco are from British Columbia in Canada. So it's worth viewing this through that lens. The Ride Aligned rider ability scale runs from beginner through to professional. If you're not sure how close you are to professional, watch Bryn Atkinson ride to get a gauge on the top end of the scale.

I actually dialled myself back to Intermediate after seeing that. When first testing the Norco Optic C2 on release in late 2019, the Ride Aligned software made a huge difference in setup. The software is an excellent guide to get you started, and I've settled between Intermediate and Advanced, with a couple of changes to bar width and stack height that I find works better. Ride Aligned isn't gospel, but it really helps to get your setup very close to perfect, as long as you're honest with your ability. There are tips on further fine tuning as well, all on the website.

With the Optic C3 already being the workhorse to test the Microshift Advent X group set (stay tuned for next issue), when Shimano released the new Deore M6100 12-speed group set and Fox unveiled a 34 GRIP2 fork, it seemed like an ideal time to strip the Optic down and build it as a full-custom bike. Throw in the Shimano XT trail wheels, Maxxis Minions in Dark Tan, and PRO Tharsis 3Five cockpit and the finished product looks hot.

Building up a Shimano Deore M6100 group set

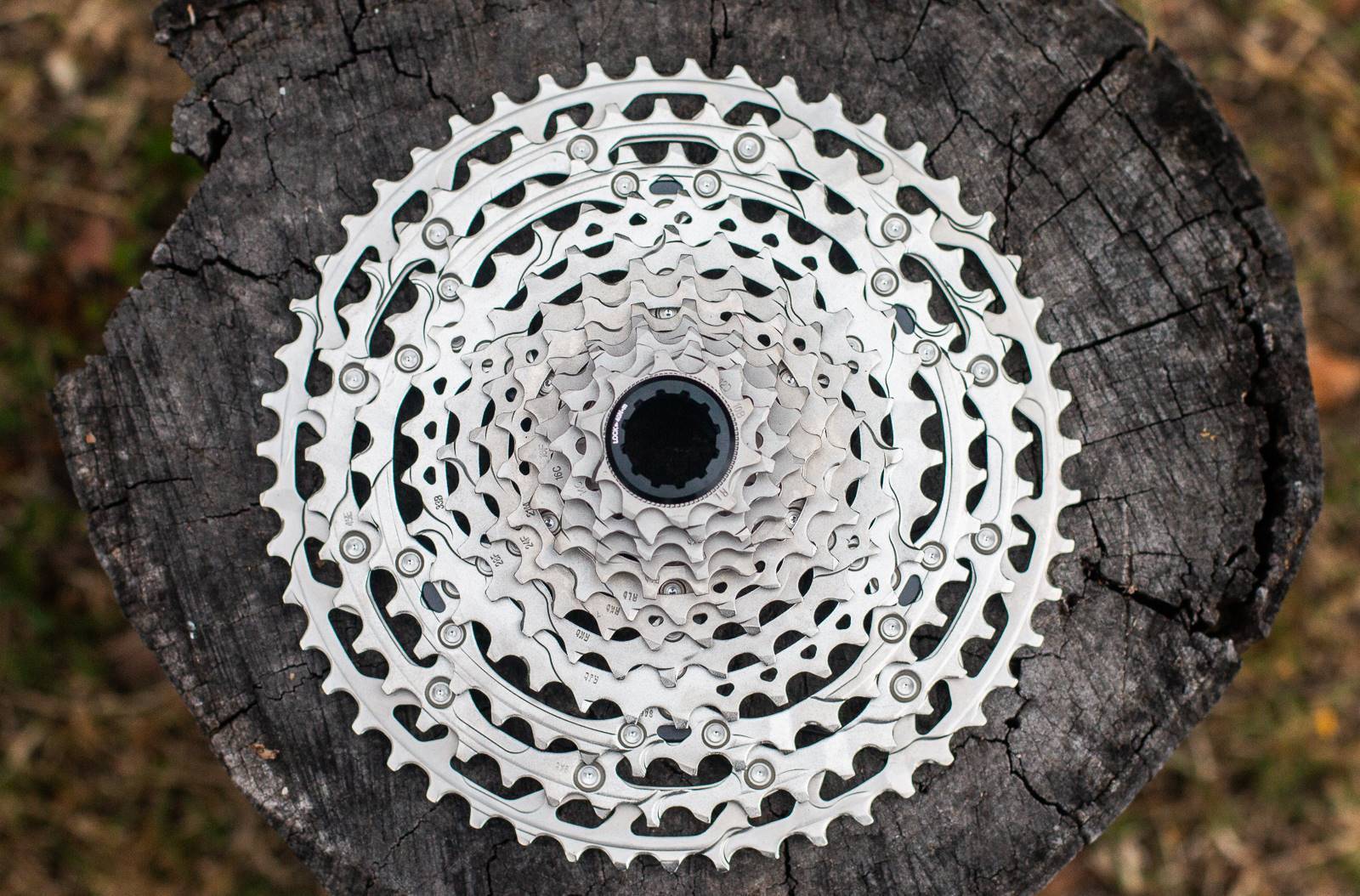

This was the first time I'd got to 'touch and feel' the new Deore 12-speed, and it's very impressive as to how similar it is to SLX, Deore XT and XTR. That's not to say it's the same, there are changes in materials and production that increase the durability and performance of the top end gear. Each item is cross-compatible which means you can spend a bit more, or a bit less, where you want to.

One of the most notable changes would be the cranks as they aren't Hollowtech. So instead of being arms that are hollow inside, they are sculpted through the back. The result is they are a bit heavier than a higher end crank set. The chain ring is a little more basic but the shaping of the teeth remains, which is where Shimano get such good chain retention and quiet running from. They are completely interchangeable with SLX, Deore XT or XTR chain rings if you need a size beyond the 30t and 32t options with Deore. This opens up 28-38t options, but clearly the top end rings cost more.

The whole system was really easy to build up, and with the iSpec EV mounts the shifter and dropper lever attached to the brake levers for a really neat cockpit, especially at the Deore level.

The iSpec EV mounting allows about 5 degrees of rotation, so you can adjust where your shifter or dropper lever sits in relation to the brake lever height. But you still get 14mm of in and outboard adjustment, which is perfect for fine tuning where you have your levers and where you want your shifter and dropper lever to sit in relation to your hand position. On Deore XT and XTR you get a much wider range of rotational adjustment, so if you're very particular in your setup, that might need to be where you look.

Tuning of the shifting is really simple, and like all 12-speed group sets B-tension is a big part of getting it right, once you have the limits and cable tension set. All the Shimano 12-speed rear derailleurs have a little guide on the inner plate. Typically the B-tension screw is way out.

With the drivetrain in the 51t, you back off the B-tension screw until the guide sits in line with the 51t sprocket. I had to take another link out of the chain after this but that's easy.

The Deore M6100 rear derailleur does away with external clutch adjustment, beyond the on/off switch which helps when removing or fitting your rear wheel. What you might notice in the stand is how much of an impact switching the clutch on makes to the shift load at your thumb. Getting it just right for the rider, the bike and how you ride makes for the ideal setup. You can still adjust the clutch, you just remove the three allen keys to access it. I took the liberty of applying a little more of a light grease to the clutch mechanism as they can dry out a little over time. The shifting should now have all the chain security needed with a pretty light touch.

A few more changes were made, including trimming the bars to 760mm. Yes, that is narrower than what the Ride Aligned software recommends, but after hitting my pinky fingers a couple of times it was time to break out the blade and cutting guide. Given the closed end Pro grips add a little width anyway, the functional width is still probably 770mm.

And now, the on the trail setup begins. With a different fork to the stock RockShox Pike, I am going against the logic of the Ride Aligned system. But given the Fox 34 GRIP2 has so much adjustment possible, tuning in the ride shouldn't be a problem. We'll have some more details on the group set, wheels and fork as the testing process goes on.