Pirelli release the Scorpion MTB range

Pirelli have jumped into the mountain bike game - but not without some proper research befitting the high performance brand.

Pirelli have added to their tyre line by bringing the winning Scorpion marquee across to the world of mountain biking. We were invited to the global launch in Sicily, Italy, to learn more about the tyres and test them on the volcanic terrain of the island.

Having jumped back into the cycling world in 2017 with their range of PZero Velo road tyres, mountain bike tyres were the next logical step for the premium Italian tyre brand, and they have brought four tread patterns to the trail for two wheels sizes, with three widths and two different casing options.

The Scorpion name comes from the performance motorsport range, and even some of the tread shapes will look similar to those who know motocross. But this hasn't been done on a whim, Pirelli have done their research into what works. And their range is designed to be far simpler to choose from than what other brands offer, with one rear specific tyre, then one for hard conditions, one for mixed, and one for soft.

“The DNA of Pirelli is based on products that perform,” says Piero Misani, head of Business for bikes and motorbikes. “We spend more than any one else on research and development, we spend 6.5% of our turnover in R&D.” And that is one reason why we are sat on the side of Mt Etna in Sicily. Pirelli has one of their major testing centres on the island, and given the altitude differences afforded by having a huge, active volcano, Pirelli have about 6 different ecologies to test their tyres in. Be that for two wheels or four. While Pirelli supply F1 and the Superbike World Championship, the Pirelli Velo business looks after tyres for people like us – mountain bikers.

Pirelli Velo is concerned with bike tyres, but it doesn't change what is at the heart of the Italian tyre company. “The DNA of Pirelli is based on products that perform,” adds Misani. In developing the Scorpion range of mountain bike tyres, Pirelli had over 1400 engineers work in the research and development for the tyres.

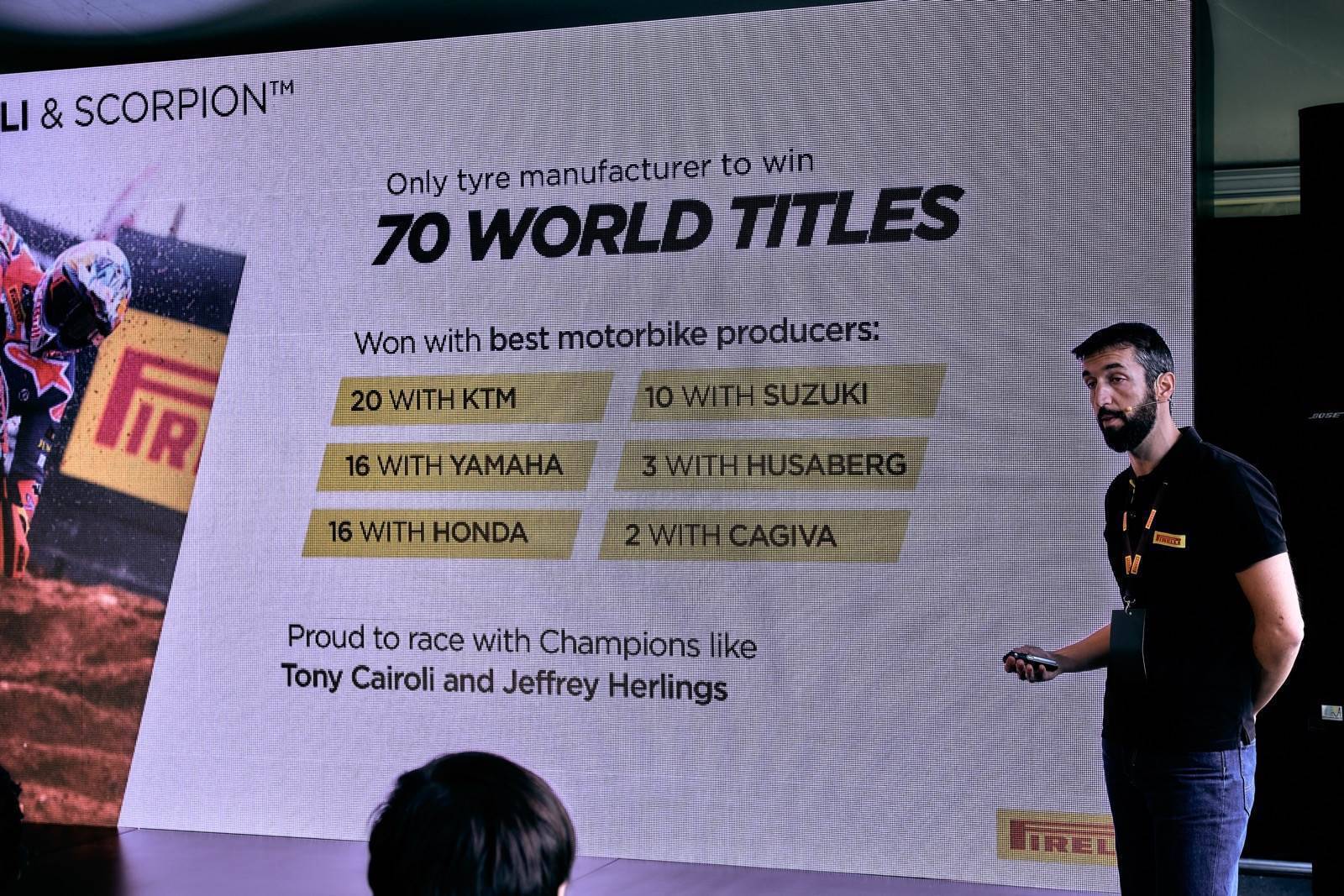

The Scorpion name has heritage for Pirelli with 70 world titles in motorsport. “It gives an expectation of performance. It was a pretty bold decision to use this flagship name,” said Samuele Bressan. He went on to explain that choosing mountain bike tyres and categories of riding can be difficult to understand, especially for brands offering different casings, treads, rubber compouns and of course sizes. Instead, Pirelli define their tyres by the riding style.

“We won't be talking about XC, all-mountain and enduro – more about the riding style,” says Bressan. The idea is that the tyres are easy to choose, and easy to use. “We aim to have riders choose a tyre based on the consistency of the terrain they ride.” And so while there is a tyre optimised for use on the rear, there are then front tyres for Hard conditions, Mixed conditions, or Soft conditions. Of course, you can mix and match.

Creating the Scorpion Mountain Bike range

Giuseppe Matrascia, one of the head engineers at Pirelli, stated that there are similarities with their Scorpion motocross range and the Scorpion mountain bike range of tyres.

“Some elements of the tread patterns are common to the motocross Scorpion range. The four treads mix knob size, height, spacing and rubber bridges.”

A lot of research went into the role that each tyre needs to play – and each tread knob. “The edge knobs on the Hard tyre are designed for a good safety feeling for a high lean angle,” explains Matrascia as an example. “The triangular knobs of the soft version help evacuate the mud. On the rear, the rubber bridge at the tread base helps with better stability.”

Pirelli designed the Scorpion treads to suit the terrain. Then with three widths available in two wheel sizes, it's about choosing the right size for what and how you ride. Pirelli feel that the Scorpion range offers tyre options for everything between the two extremes of World Cup XCO and Downhill.

When testing the tyres, they mixed data gained from indoor lab test to professional test rider feedback. This allowed engineers to fine tune the product.

Salvatore Pennisi is Pirelli's head of testing and put the details of how much time they spent testing in front of us.

– 95000m of climbing

– 450 tests on different surfaceses and temperatures

– More than 120 data recording sessions

– 140 different Scorpion prototypes

– More than 800 prototypes fitted on rims

– More than 30000km/year on the Scorpions

– All tests on on 2.2” and 2.4”

– 8 testers used

– Testing took place 12 months year, with 200 days per rider or 1600 days of testing in a year

– They used 10 different mountain bikes as a base fleet

– Pirelli tested with 7 different rim widths

Pennisi explained that 90% of tests have been blind. So the engineers knew what the changes in casing, tread or rubber were, but the testers didn't. They just had to provide feedback and gather data.

Tyre sizes, casings and compounds

So, four treads, two wheel sizes, three widths and two casings. That still ends up as a lot of tyre models. So let's break it down. The 29×2.2” and 29×2.4” sizes are available in the normal models, and a LITE model. The Lite has greater width and length on the contact patch – which means it has less rolling resistance but less sidewall strength. It's also lighter too, obviously, saving about 35-40g from a standard model. The 2.2" measures 58mm across the bag when inflated on a 25mm internal width rim, and the 2.4" measures 61mm when inflated on a rim with a 30mm internal width.

“We have a standard version and a LITE version,” explained Pirelli's head MTB tyre designer. “But it's not reinforced or not reinforced. In 2.2” the casing is 120tpi with an extra 120tpi sidewall reinforcement. And the LITE doesn't have the additional sidewall reinforcement. In 2.4” the usage is different, on a trail bike. The standard version is 60tpi for better stability and using it with a heavier bike, on less prepared trails. There is then an additional 120tpi of sidewall reinforcement. The LITE version is 120tpi, with a 120tpi reinforcement. So it's a lighter tyre. But the standard model is stiffer, and stronger. But neither tyre is without reinforcement, as it wouldn't make sense for a tyre in the 2.4” size.”

Currently, the 2.6” tyres are still in development, and 27.5” sizes will be available in September.

What is really interesting is the very tailored development in knob shape, sizing and location from one tyre size to the next. From knob height, spacing, sipes and spacing, each tyre size has been customised after extensive product testing and research. This is to suit the extra mechanical forces that go into the tread on bigger tyres, for better support in the turns. Each single model has had specific design and refinement. Even a 27.5×2.4” to 29×2.4 will have differences in the lug shapes, sipes and tread depths on otherwise the same tread pattern.

SmartGrip Compound

Pirelli use a single compound for each tyre, although each compound has been tailored for a given tread pattern. The single compound gives a long life to sharp edges, so there is no dry and wet performance drop over time. Most others use a multilayer compound, using a mix of soft and hard compounds. But the soft compound has quick wear, moving to the harder compound below and dropping performance very quickly. Pirelli have a specific compound for each tread design and tyre structure. The Hard surface knobs are softer, the soft are harder for better penetration. Hard tyres have a fast damping, while soft has slow damping. This assists grip via stability.

“It's a single compound, called SmartGrip," we are told by Pirelli's tyre designer. "We have a trade off between tread wear and grip. We developed this compound and tuned it for each tread pattern. On the Hard models the tread isn't there to penetrate the soil. You need the compound to adapt to the terrain. It has a lot of tread contact or what we call a high land:sea ratio, how much knobs contact the ground compared to the overall contact patch. So it's a large surface that needs to adapt, it is a softer compound. But then on the Soft model, the grip is made from the knobs penetrating the soil and creating a mechanical grip. So you need a stable base and the compound needs to be stiffer to make it stable. But the damping is another aspect to tune, to then help with grip in the wet. By tuning the damping we control how long the tyre is in contact with the ground for.”

So between the models, the tread patterns and compounds work together to create the best grip for the given purpose. It makes sense.

Rim widths and tyre size

Rim widths and tyre size

We have played around with rim widths and looked at how they change how a tyre performs. And Pirelli did just the same, and say their 2.2” tyres are optimised for a 25mm internal width, while the 2.4” are optimised for a 30mm internal width rim.

“We started with development on different rim widths, and saw that the width effects the behaviour of the tyre,” said Pirelli’s designer. “We focused on the 25mm for 2.2” as from both indoor lab testing and outdoor testing, we monitored the internal volume of air and saw that on 25mm it is maximised. It’s not a linear relationship that you make the rim wider and the volume of air increases. At a certain point the shape is deforming and the diameter is getting lower. For 2.2” 25mm is optimal for the volume of air and the profile of the tyre – not too flat, nor too round. You can still use a different rim width.”

The same methodology was used in determining that a 30mm inner width was best for the 2.4” tyre. As the 2.6” models are due to be ready in September, I asked what width they would be optimised for.

“We have seen rims getting wider, up to 40mm. Big manufacturers of rims are pulling back from going too wide – at a point it stops offering an advantage in comfort and handling. I think the 2.6” will be ideal for 30-35mm.”

The details and numbers

The Rear specific and Hard, Mixed and Soft terrain models are currently available in the following models.

29”: 2.2”, 2.2” LITE – available March

2.4”, 2.4” LITE – available April

27.5” sizes and 2.6” widths will be available towards the end of the year.

The weights are competitive, with a Scorpion H LITE in 29×2.2” weighing a claimed 660g – so about the same as a Maxxis Rekon Race EXO in 2.25”. It is worth noting that the Pirelli 2.2” casing measures up a little wider when inflated than a Maxxis 2.25” casing.

We have 6 tyres that we are currently testing, and the weights are about 60g over and 25g under the claimed weights. It is worth noting that the variance is far from abnormal for tyres.

The tyres do seal up easily with a track pump, and hold air when setup tubeless without sealant. This is a good sign for their strength, and the reliability of a tubeless system – as long as your tape and valve are in good shape.

Initial impressions

I had a Mixed front and Rear specific tyre fitted when in Italy, and rode on them there in a variety of terrain, including a lot of very sharp volcanic rocks. This combination is meant to be the most versatile. And since the slopes of Mt Etna I have also ridden them on a variety of dry and loose trails in south east Queensland, and in the Otway Ranges.

Both tyres inflate to a really good bag size, and are wearing really well, considering they have had some use on the road as well. The casing has been really stable, even when running around 20psi. And while the conditions on my home trails are fairly typical late summer dust bowls, the conditions in the Otways were fast with a slight coating of skatey in places – a perfect opportunity to test how predictable their break away point was, espeically considering I had a plate on the bars.

The rear broke away a little when really pushed, but it was highly predictable. The front did continue to dig in, especially with a slight forward bias when pushing into corners.

When you’re handling the tyres you really notice that the casing feels like it has a lot of stability to it, especially comparing the 29×2.2″ tyres to other XC/trail type tyres. The 2.4″ also feels far more sturdy than say, the 2.6″ Maxxis Rekon I tested in 2018. The sidewall stability and casing strength means the tyres do respond better to a slightly lower pressure without flopping around.

Since then I have fitted a Soft model on the front with a Hard on the back, which is another viable combination. The Soft looks like it would just suit wet conditions, but it has dug in for traction on the looser dry terrain at home, with the Hard model feeling fast and grippy in the back – although with less braking traction than the Rear specific.

So how do they compare?

The Mixed and Rear combination are a bit like one of my favourite combinations – a Maxxis Ardent Race and Ikon, but with a bigger overall bag size and better predictability when lent over in a corner.

We have a 2.4” test set in the Victorian Alps being tested right now, and given they weigh about 900g each and have a really full bag, I do wonder if they will be a good competitor to some of the 2.35 or 2.4″ Maxxis Minions, or Aggressors, or a Schwalbe Nobby Nic. The casing and compounds are really dialled. We’ll wait to hear back after more hours are spent on the tyres, so stay tuned for a full review of the tyres in Issue #174, out on 25th March.

As it stands, Pirelli’s jump into the mountain bike market looks to be well considered. The casings, tread design and compounds are performing, and while they are a touch heavier than some of their competition, the durability and tread life looks to really be at a high level. The question is, will the 2.4” and 2.6” models (when available) be able to trump some of the current favourite tyres? Some gravity riders might not feel that the same tread pattern as a 2.2” tyre for a cross-country rider will work for them on a larger casing, and vice versa. But the reality is that Pirelli have moved away from creating so many tyres that their specific use gets a bit confusing, and instead have created the four tread patterns for conditions – you just choose how you ride via the sizing. So far I’m impressed, really impressed.

RRP: 2.2” – $79

2.4” $85

From: FE Sports